UV Light Cure Adhesives

UV light cure adhesives are solvent-free resins employed for rapid, low temperature curing in fabrication of electronics components. They are especially important when precise alignment of parts and/or short production time is desired. Various types of adhesives be cured by UV light, but most of the commercial adhesives are acrylate- or epoxy-based.

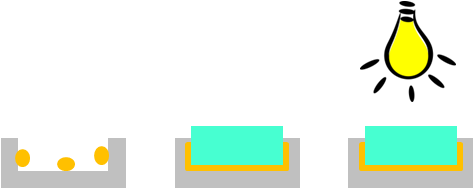

dispense mate cure

ACW offers epoxy-based UV cure adhesives which provide a number of advantages. The adhesives have low reactivity including no interaction with LCD and OLED materials. The cured adhesives have high Tg, low outgas, low CTE, and low gas and moisture permeability. They are compatible with solder reflow temperatures and meet many reliability standards such as Telcordia and JDEC Level 3. Bonded parts survive temperature cycling with very small shifting.

ACW UV cure adhesives are employed in electronics and optoelectronics applications such as active alignment, fiber to V-groove bonding, waveguide assembly, chip edge sealing, and LCD and OLED device sealing. They are designed for UV-transparent substrates. For opaque substrates or assemblies with shaded regions, see the Dual Cure Adhesives and UV-Snap Cure Adhesives pages.

Applications: glass to glass bonding, glass to ceramic bonding, glass to plastic bonding, semiconductor or optoelectronic packaging, component packaging, edge sealant for OLED, PLED displays, edge sealant for liquid crystal chip, fiber array and waveguide bonding. These adhesives can be used in active alignment applications.

| Product | η (cps, 25 °C) | Tg (°C) | Applications | Data Sheet |

| A535-A | 1,000 | 155 | A, B, C, G | TDS |

| A535-AN | 4,000 | 175 | A, B, C, G | TDS |

| A586 | 5,000 | 110 | A, B, C, G | TDS |

| A1428 | 6,000 | 115 | D | TDS |

| A1450-TX | 42,000* | 165 | D, E, I | TDS |

| A535-XF | 12,000 | 148 | A, B, C, G, H | TDS |

| A535-AN-TX | 12,000* | 170 | A, B, C, G | TDS |

| A1430-B | 80,000 | 110 | D | TDS |

| A1432 | 60,000 | 150 | B, D, F, G | TDS |

| A1445 | 28,000 | 96 | A, B, C, G, I | TDS |

*Thixotropic, the viscosity is at a shear rate of 10/s.

APPLICATIONS

A: Bonding

B: Semiconductor, chip & component packaging

C: Fiber/waveguide bonding

D: OLED/PLED edge sealant

E: Flexible OLED device edge sealant

F: Liquid crystal device sealant

G: Active alignment

H: Filters visible and near IR light

I: Glob-top Encapsulation and Bonding