UV-Snap Cure Adhesives

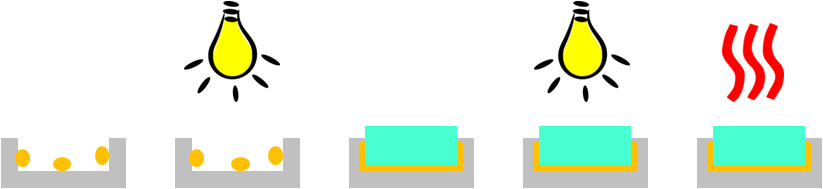

UV-Snap Cure Epoxies are designed to bond opaque or shaded temperature-sensitive substrates. The one component adhesives are stable at room temperature. The adhesives are dispensed and then activated by a short UV irradiation step, which does not produce a surface skin on the epoxy. The parts are mated and aligned, and an optional second UV irradiation fixes the component if precise alignment is necessary. Finally, a thermal step that can be as low as 60 °C completes the curing. These epoxies are available in normal viscosity and thixotropic versions. For more discussion, see UV-Snap Cure adhesives.

dispense activate mate fix cure

Applications: glass to glass bonding, glass to ceramic bonding, glass to plastic bonding, semiconductor or optoelectronic packaging, component packaging, active alignment applications, and camera module assembly. Three products are listed in the table below; CONTACT US if you are interested in trying a UV-Snap Cure product with a higher viscosity.

| Product | η (cps, 25 °C) | Tg (°C) | Applications | Data Sheets |

| A535-S | 2,700 – 3,200 | 155 | A, B, C, D, E | TDS |

| A535-TXS | thixotropic, 9,000* | 160 | A, B, C, D, E | TDS |

| A1452-S | 3,200 – 3,800 | 150 | A, B, C, D, E | TDS |

* Viscosity for thixotropic paste measured at a shear rate of 10/s.

APPLICATIONS

A: Bonding

B: Semiconductor, chip & component packaging

C: Active alignment

D: Die-attach

E: Compatible with PC lenses and optical components in camera modules