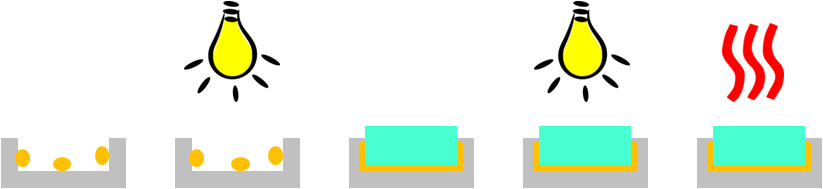

ACW’s UV-snap cure epoxy adhesives offer a unique bonding approach for components that contain shaded areas and parts that are temperature sensitive. The bonding sequence discussed on the UV-Snap Cure page and shown below is somewhat complicated, but one has several options when using the UV-snaps. The second UV step can be skipped if one does not require high precision and active alignment. In addition, because the activation step produces a very fast curing epoxy adhesive, it is possible to stop after the mating step, and the adhesive will cure in about one day.

dispense activate mate/align fix fully cure

As one might expect, the properties of the adhesive will be affected by the processing sequence. In order to understand how a typical UV-Snap behaves with different curing conditions, we tested several possibilities and used lap shear on a mechanical tester to evaluate the strengths of the bonds. The test strips were made from 375 micron PC with a one-cm wide strip bonded to a two-cm wide strip and a bonding area of one cm2. The results are shown in the chart below where we record Kgf/cm2. The bonding can be very strong as expected for an epoxy adhesive, reaching a limit in our test of 25 Kgf/cm2 (ca. 350 psi) which results when the 375 micron PC starts stretching.

The best results were obtained when the UV-snap was cured at 80 °C for 30 minutes, irrespective of whether a UV-fix step was used. If one delays before heating to 80 °C, the bond is weakened, because partial curing occurs at room temperature which does not give the higher adhesion. Nonetheless, even curing at room temperature with no heating at all gives reasonably strong bonding of about 8 Kgf/cm2 (ca. 110 psi) that might be acceptable in some applications.