Photo nanoimprint lithography (P-NIL) processes are cost effective methods for production of diffractive optical elements (DOE) used in holographic displays. A limiting factor for this method is the environmental stability of the P-NIL resin. If the P-NIL material yellows considerably with aging, the DOE with have limited utility. In automotive applications, for example, the DOE will experience considerable temperature variations but is expected to operate for years.

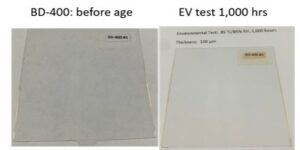

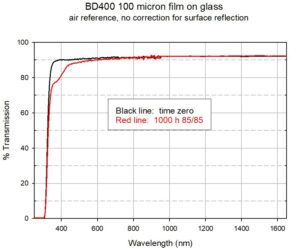

ACW’s BD-400 P-NIL resin was specifically designed for harsh conditions. When a 100-micron film of BD-400 coated on glass was exposed to 85 °C and 85% relative humidity (85/85) for 1000 hours, no cracking or delamination of the film from the glass was observed (figure below). Importantly, as seen in both the figure and the before-and-after spectra, high light transmission was maintained for the entire visible and near IR regions.

Want more information? See the data sheet at BD400 TDS or click on the image to open a PDF describing P-NIL resins for DOE.