BD-400 is a high-performance photo nano-imprint lithography (P-NIL) resin. In P-NIL, a thin layer of resin is coated on a mold or substrate and cured with UV light to give a positive pattern with resolution at the 10’s to 100’s of nanometer level. BD-400 resin has excellent flow properties and can be spin-coated. Its films have high hardness, high heat resistance to solder-reflow conditions, and a high glass transition temperature (Tg = 139 °C). The result is good stability under extreme conditions such as those found in automobile applications.

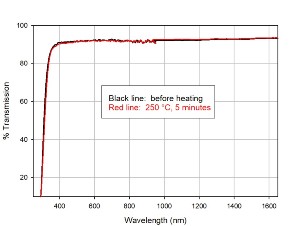

The stability of BD-400 films is demonstrated in the UV-vis and Near IR spectra shown below. The black spectrum is from a BD-400 film between glass plates after preparation at room temperature. The assembly was then heated at 250 °C for 5 minutes to simulate solder reflow temperatures, and the red spectrum was obtained. Under these conditions, there was no indication of coloration in the visible region (380-740 nm) much less the Near IR region used for LiDAR sensors. Check out the Data Sheet at BD-400 TDS.