Are you searching for high scratch resistance protection for your plastic or glass devices? ACW has a suggestion for you, try ACW’s new hard coat HC-6000. HC-6000 is a hybrid organic/inorganic hard coat containing colloidal silica nanoparticle dispersion. The inorganic filler results in low shrinkage and high hardness, and ACW’s expertise provides a fast UV-cure in air for thin films of only 5-7 microns. In a nitrogen atmosphere, HC-6000 can be cured in sub-micron thicknesses making it an excellent binder for metal nanoparticles in conductive film.

Cured HC-6000 hard coat displays superior properties. Adhesion is very high for both plastic and glass substrates. A 6 micron film on PET has 3H-4H pencil hardness, and a 6 micron film on PC or PMMA has 4H-5H pencil hardness. Thicker coated films of HC-6000 do not crack, and HC-6000 films are flexible without cracking for a small bend radius.

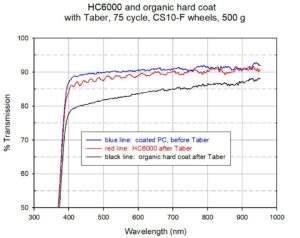

The outstanding property of HC-6000 is its scratch resistance which is demonstrated in the spectra shown below. The blue line is light transmitted through PC coated with a 6 micron film of hard coat; the ca. 10% reduction of light is due to normal reflection of the surfaces. The black line is the transmission spectrum obtained when a high quality organic hard coat on PC was scored with a Taber abraser, and the red line is the spectrum obtained after abrasing HC-6000 coated PC with the same conditions. The haze of the organic hard coat sample is about 4 times as great as that of the HC-6000 coated sample.

For more information, see the data sheet at HC6000 TDS or contact us at info@addisoncw.com.