Dual Cure Adhesives

ACW’s Dual Cure adhesives are epoxy-only resins that can be cured with UV light or heat. They are designed for use in electronics and optoelectronics fabrication where the component has shaded regions that cannot see light and/or temperature sensitive parts that cannot be heated to the relatively high temperatures needed to fix thermal cure epoxies. The processing sequence for dual cure epoxies is to dispense the adhesive, mate the parts with active alignment if necessary, irradiate the assembly with UV light to fix the alignment, and then heat to fully cure the adhesive in shaded regions. The sequence is shown schematically below. In a real-life example, one can fabricate a camera module assembly that contains an opaque liquid crystal polymer holder and a polycarbonate (PC) lens barrel that cannot be heated above 90-100 °C.

dispense mate & align fix fully cure

Most dual cure adhesives are mixtures of monomer types, one type that reacts photochemically and another that reacts thermally, but ACW’s dual cures are epoxy only. One advantage of this design is that the cured resin is uniform, containing no regions of uncured materials. In addition, epoxy adhesives display high adhesion and good environmental properties that make them the adhesives of choice for demanding applications. The disadvantage of an epoxy compared to an acrylate is that curing is slower, although relatively slow curing might actually help in adhesion, and the curing process for epoxies continues after the light or heat is removed.

The trick for epoxy only dual cure adhesives is that the epoxy polymerization must be cationic irrespective of whether the process is initiated by UV or thermal activation. Conventional thermal cure “two-part” epoxies, including those premixed and shipped at low temperature, involve reaction of a basic polyamine with a polyepoxide, but that approach cannot be used in a dual cure epoxy because the UV initiators for epoxies produce acids. Conventional thermal acid-generators for epoxies require relatively high temperatures for initiation and the polymerization reactions, but that is not compatible with thermally sensitive parts. ACW uses proprietary methods to achieve relatively low temperature acid production.

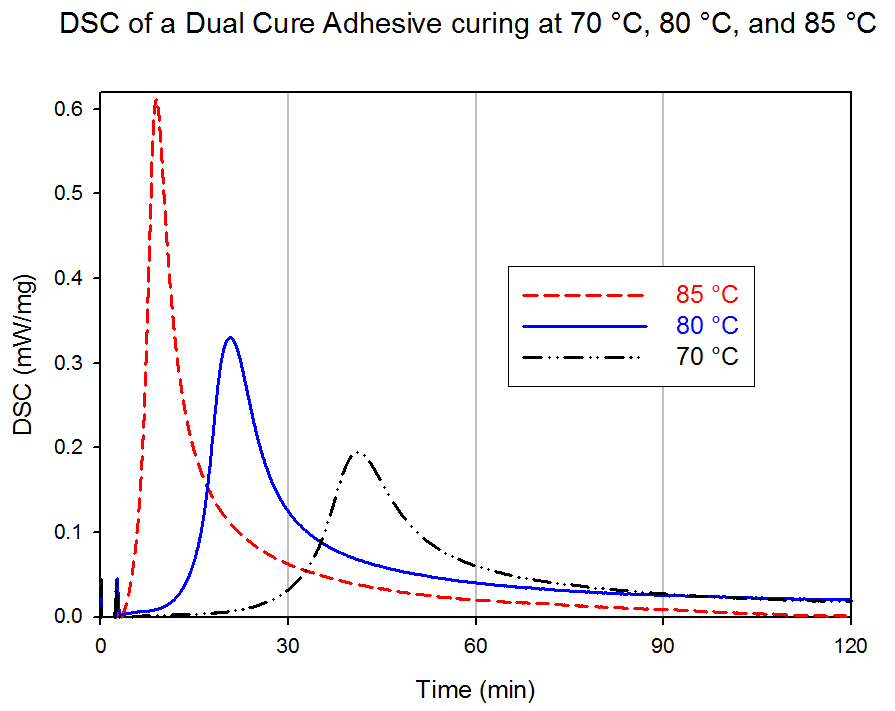

Depending on the application, the target for the thermal step of a dual cure epoxy is in the range of 80 °C to 150 °C. We evaluate the thermal cure of our dual cure adhesives by using a differential scanning calorimeter (DSC) under isothermal conditions. The uncured epoxy is rapidly heated to the temperature of interest and held at that temperature. The DSC measures the heat generated by the polymerization reaction. Results for a highly reactive ACW Dual Cure epoxy are shown below where the curves are standardized for one mg of adhesive. The initial increase in heat reflects the generation of increasing amounts of acid and more rapid polymerization. After reaching a maximum, the reaction slows in an exponential decay as the epoxy is consumed.

In summary, ACW’s Dual Cure Epoxy Adhesives offer a unique solution for fabrication of components containing shaded regions and temperature sensitive parts, allowing UV fixing for active alignment and relatively low temperature curing for the shaded regions. The cured adhesives have superior adhesion typical of epoxies and high Tg providing excellent environmental performance. For a detailed list of the Dual Cure epoxy adhesives offered by ACW, see the Dual Cure Adhesives product page.