Photo-Nanoimprint Lithography (P-NIL or UV-NIL) is a versatile technique for low-cost nanoscale device fabrication with a wide range of applications. As automobiles with increasing numbers of detectors evolve, opportunities for P-NIL fabricated lenses will increase. But, for the automotive industry, P-NIL materials must survive extreme stress conditions required to demonstrate automobile efficacy. BD-400, ACW’s premier P-NIL resin, is up to the tough challenge of the automotive industry.

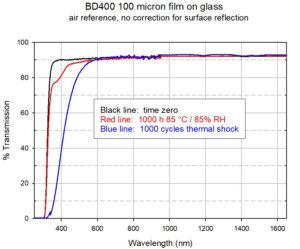

We coated glass plates with BD-400 resin at a thickness of 100 microns and exposed the coated plates to extreme conditions. One set of coated plates was placed in a thermal shock chamber, where the temperature changed within seconds from -40 °C to 150 °C and back every 30 minutes (cycle time of 1 hour), for 1000 cycles. Another set of coated plates was placed in a humidity chamber at 85 °C and 85% relative humidity for 1000 hours. These conditions are severe even for automobile components.

The figure below shows the results of the stress tests. The UV-vis-Near IR spectra of the thermal shock plate displayed yellowing due to the high heat treatment in the thermal shock test but little or no reduced transmittance for much of the visible and all of the Near IR regions. The environmental 85/85 sample showed high transmission for all of the visible and Near IR regions. Importantly, no delamination was observed in either stress test.

Click HERE to open the data sheet BD-400. For more information, contact us at info@addisoncw.com.