Camera Module Adhesives

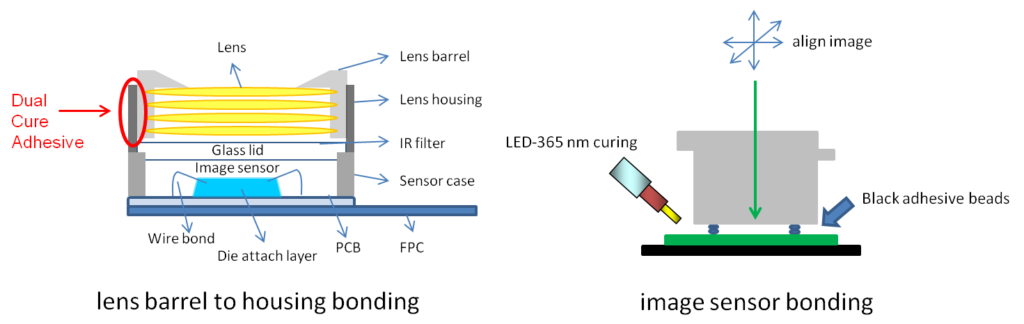

Camera module design and fabrication has rapidly evolved as components are reduced in size and resolutions are improved. The high precision necessary for camera modules requires active alignment methods where an adhesive is dispensed in precise positions, components are mated, the assembly is oriented with active alignment, and the aligned assembly is fixed by UV curing. Because the assembled component contains shaded areas, dual cure adhesives have been designed that can be cured by both UV light and heat.

Many dual cure adhesives contain two distinct resins and initiators for the UV and thermal processes. Addison Clear Wave’s approach to highly demanding dual cure applications such as camera module assembly has been to develop single component epoxy resins that contain both UV and thermal initiators. This unique design avoids problems arising when a portion of the adhesive in shaded areas remains uncured after the thermal step or an internal mismatch arises. Moreover, it offers the advantage of working with epoxy-only formulations that can be cured to high Tg and high reliability resins with outstanding adhesion and environmental properties.

ACW’s dual cure epoxy adhesives for camera module packaging are thixotropic with varying viscosity. They cure rapidly with either UV (mercury, metal halide, LED 365 nm) or heat (85-90 °C for 60-120 minutes). Representative adhesives are listed below; contact us for more options including black versions at info@addisoncw.com.

| Epoxy | η (cps)* | TI** | Tg (°C) | Data |

| A1851-TX | 11,000 | 3 | 164 | TDS |

| A1853-TX | 65,000 | 7 | 165 | TDS |

| A1855-TX# | 65,000 | 7 | 180 | TDS |

| A1859-TX | 90,000 | 5 | 161 | TDS |

*Thixotropic resins; the viscosity at 25 °C and a shear rate of 10/s is listed.

**Thixotropic Index: η at shear rate 1/s over η at shear rate 10/s.

#A1855-TX has high depth of UV cure (750 micron) in addition to thermal through cure to any depth.

A general discussion of ACW dual cure epoxy adhesives can be found on the Dual Cure blog page, and a detailed listing of ACW’s dual cure epoxies for various applications is presented on the Dual Cure Adhesives product page.